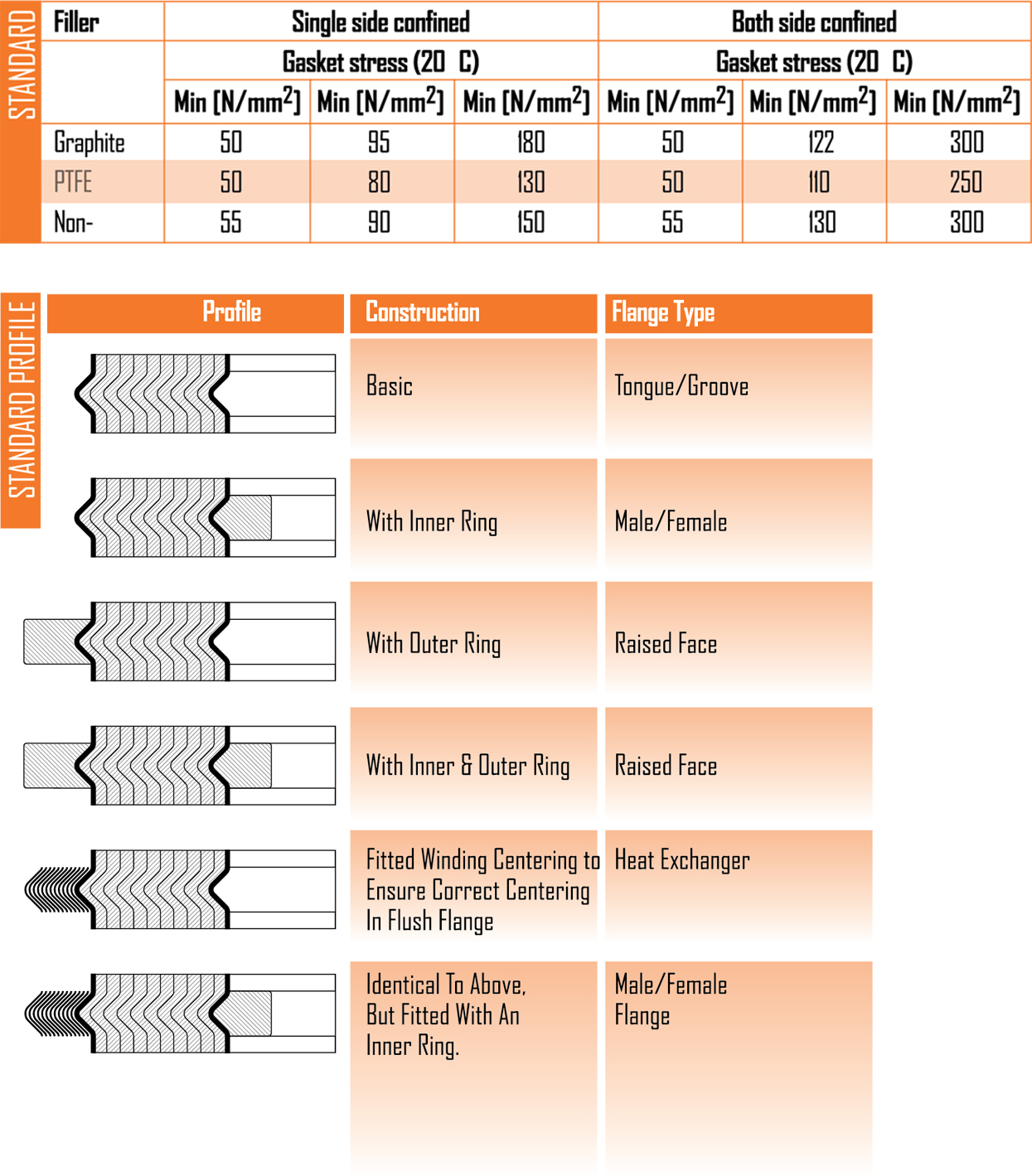

consist of V-shaped metal strip spirally wound in combination with a soft, filler materials. The metal strip provides outstanding recovery, guarantees excellent sealing.

Due to this combination of materials, its suitable for sealing under severely fluctuating temperature and pressure conditions. Depending on the application of the spiral wound gasket can be specified with outer and inner rings.

- Suitable for use a wide range gasket stress range.

- Can be used to seal fluid pressure up to 250 bar and from cryogenic temperatures uo to elevated temperatures of 1000°c.

- Simple to install without being damaged (although extra care should be taken during transportation and installation of large diameter gasket without inner or outer guide rings).

- The outer guide ring simplifies assembly and prevents blow-out of the gaskets.

- By combining different winding materials and metals, the gasket can be tailored to suit a wide variety of operationg conditions.

- Easy to remove after service.

- Does not cause any damage to the flange faces.